Ingredients - Glass fibers in a Bis-GMA based resin matrix (Luxapost) - Rustproof, hardening steel (Luxapost drill) Recommended Speed - Approx. 1000 rpm Available Product sizes - Post length = 16mm for all diameters

Ingredients - Glass fibers in a Bis-GMA based resin matrix (Luxapost) - Rustproof, hardening steel (Luxapost drill) Recommended Speed - Approx. 1000 rpm Available Product sizes - Post length = 16mm for all diameters

Ingredients - Glass fibers in a Bis-GMA based resin matrix (Luxapost) - Rustproof, hardening steel (Luxapost drill) Recommended Speed - Approx. 1000 rpm Available Product sizes - Post length = 16mm for all diameters

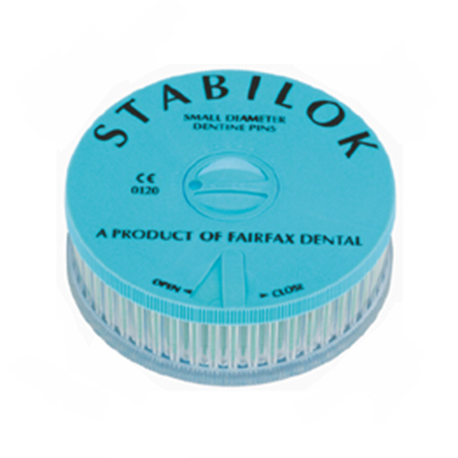

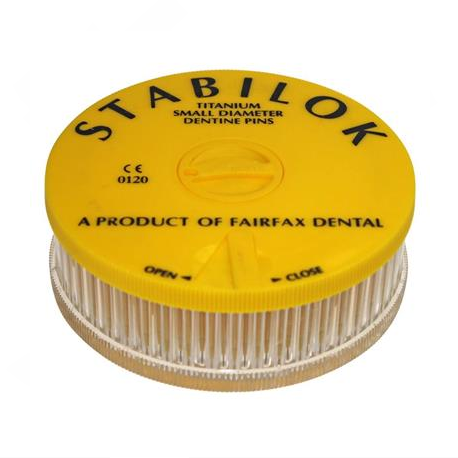

STABILOK DENTINE PINS INSTRUCTION SHEET Overview: Stabilok Dentine Pins are an effective and economical way to provide extra mechanical retention for restorations in both anterior and posterior teeth. Once in place in the tooth, they can be reduced in length and/or bent into the desired position. A major advantage of Stabilok Dentine Pins is that the pin is securely held in a contra-angle shank until it is ready to automatically shear off in the tooth at the correct depth. Preparation of the tooth: The tooth that requires placement of a Stabilok Dentine Pin should be cleared of all caries and dried with an air syringe. In general, a separate Stabilok Pin will be required for each cusp missing. A pre-operative radiograph may be useful in identifying the position and size of the pulp. Procedure for placing the Stabilok Pin: Place a Stabilok Twist Drill in a contra-angle handpiece and latch it in place. With the motor running at a speed of about 2000 rpm drill a hole in the dentine, taking care not to drill accidentally into the enamel or the pulp. The Stabilok Twist Drill has a self-limiting shoulder which prevents drilling too deeply. Once the pinhole has been drilled, remove the twist drill from the handpiece (the twist drill should be sterilized before it is used again). Place a Stabilok Dentine Pin in the handpiece and latch it in place. With the Pin rotating at about 2000 rpm, present the tip of the pin to the opening of the pre-drilled pinhole. The pin will then self-thread to the bottom of the pre-drilled hole and shear-off at the neck formed in the threaded portion. Modifying the Pin: Stabilok Dentine Pins can be modified by either shortening them or by bending them. SHORTENING: To shorten a pin, proceed as follows: Place a high-speed diamond or carbide fissure bur in a turbine handpiece. Position the handpiece such that the bur is perpendicular to the Stabilok Dentine Pin and at a point corresponding to where the pin is to be cut. With the bur running, gently bring the bur into contact with the pin and allow it to cut through the pin from one side to the other. A gentle axial movement of the bur to and fro will facilitate the operation. DO NOT attempt to shorten the pin before it is placed in the tooth because doing so would damage or remove the tapered tip which allows self-threading. BENDING: Stabilok Pins can be bent once after they have been placed in the tooth. An amalgam plugger can be used by applying it to the tip of the pin and gently bending the pin into the position required. The pin should not be bent more than once because repeated bending will weaken the pin and may also weaken its retention in the pre-drilled hole. Disinfection and Sterilization PINS Stabilok pins can be disinfected before use by placing them in a cold sterilization solution for 10 minutes and then rinsing them with sterile water before use. After use, the shank from which the Stabilok pin has sheared off should be disposed of carefully in a sharps container. DRILLS Before first use: Stabilok drills should be sterilized in a standard autoclave cycle. After use: Stabilok drills should have any debris, dentine etc., removed either manually or in an ultrasonic bath, and should then be rinsed and placed in a standard autoclave cycle.

STABILOK DENTINE PINS INSTRUCTION SHEET Overview: Stabilok Dentine Pins are an effective and economical way to provide extra mechanical retention for restorations in both anterior and posterior teeth. Once in place in the tooth, they can be reduced in length and/or bent into the desired position. A major advantage of Stabilok Dentine Pins is that the pin is securely held in a contra-angle shank until it is ready to automatically shear off in the tooth at the correct depth. Preparation of the tooth: The tooth that requires placement of a Stabilok Dentine Pin should be cleared of all caries and dried with an air syringe. In general, a separate Stabilok Pin will be required for each cusp missing. A pre-operative radiograph may be useful in identifying the position and size of the pulp. Procedure for placing the Stabilok Pin: Place a Stabilok Twist Drill in a contra-angle handpiece and latch it in place. With the motor running at a speed of about 2000 rpm drill a hole in the dentine, taking care not to drill accidentally into the enamel or the pulp. The Stabilok Twist Drill has a self-limiting shoulder which prevents drilling too deeply. Once the pinhole has been drilled, remove the twist drill from the handpiece (the twist drill should be sterilized before it is used again). Place a Stabilok Dentine Pin in the handpiece and latch it in place. With the Pin rotating at about 2000 rpm, present the tip of the pin to the opening of the pre-drilled pinhole. The pin will then self-thread to the bottom of the pre-drilled hole and shear-off at the neck formed in the threaded portion. Modifying the Pin: Stabilok Dentine Pins can be modified by either shortening them or by bending them. SHORTENING: To shorten a pin, proceed as follows: Place a high-speed diamond or carbide fissure bur in a turbine handpiece. Position the handpiece such that the bur is perpendicular to the Stabilok Dentine Pin and at a point corresponding to where the pin is to be cut. With the bur running, gently bring the bur into contact with the pin and allow it to cut through the pin from one side to the other. A gentle axial movement of the bur to and fro will facilitate the operation. DO NOT attempt to shorten the pin before it is placed in the tooth because doing so would damage or remove the tapered tip which allows self-threading. BENDING: Stabilok Pins can be bent once after they have been placed in the tooth. An amalgam plugger can be used by applying it to the tip of the pin and gently bending the pin into the position required. The pin should not be bent more than once because repeated bending will weaken the pin and may also weaken its retention in the pre-drilled hole. Disinfection and Sterilization PINS Stabilok pins can be disinfected before use by placing them in a cold sterilization solution for 10 minutes and then rinsing them with sterile water before use. After use, the shank from which the Stabilok pin has sheared off should be disposed of carefully in a sharps container. DRILLS Before first use: Stabilok drills should be sterilized in a standard autoclave cycle. After use: Stabilok drills should have any debris, dentine etc., removed either manually or in an ultrasonic bath, and should then be rinsed and placed in a standard autoclave cycle.

STABILOK DENTINE PINS INSTRUCTION SHEET Overview: Stabilok Dentine Pins are an effective and economical way to provide extra mechanical retention for restorations in both anterior and posterior teeth. Once in place in the tooth, they can be reduced in length and/or bent into the desired position. A major advantage of Stabilok Dentine Pins is that the pin is securely held in a contra-angle shank until it is ready to automatically shear off in the tooth at the correct depth. Preparation of the tooth: The tooth that requires placement of a Stabilok Dentine Pin should be cleared of all caries and dried with an air syringe. In general, a separate Stabilok Pin will be required for each cusp missing. A pre-operative radiograph may be useful in identifying the position and size of the pulp. Procedure for placing the Stabilok Pin: Place a Stabilok Twist Drill in a contra-angle handpiece and latch it in place. With the motor running at a speed of about 2000 rpm drill a hole in the dentine, taking care not to drill accidentally into the enamel or the pulp. The Stabilok Twist Drill has a self-limiting shoulder which prevents drilling too deeply. Once the pinhole has been drilled, remove the twist drill from the handpiece (the twist drill should be sterilized before it is used again). Place a Stabilok Dentine Pin in the handpiece and latch it in place. With the Pin rotating at about 2000 rpm, present the tip of the pin to the opening of the pre-drilled pinhole. The pin will then self-thread to the bottom of the pre-drilled hole and shear-off at the neck formed in the threaded portion. Modifying the Pin: Stabilok Dentine Pins can be modified by either shortening them or by bending them. SHORTENING: To shorten a pin, proceed as follows: Place a high-speed diamond or carbide fissure bur in a turbine handpiece. Position the handpiece such that the bur is perpendicular to the Stabilok Dentine Pin and at a point corresponding to where the pin is to be cut. With the bur running, gently bring the bur into contact with the pin and allow it to cut through the pin from one side to the other. A gentle axial movement of the bur to and fro will facilitate the operation. DO NOT attempt to shorten the pin before it is placed in the tooth because doing so would damage or remove the tapered tip which allows self-threading. BENDING: Stabilok Pins can be bent once after they have been placed in the tooth. An amalgam plugger can be used by applying it to the tip of the pin and gently bending the pin into the position required. The pin should not be bent more than once because repeated bending will weaken the pin and may also weaken its retention in the pre-drilled hole. Disinfection and Sterilization PINS Stabilok pins can be disinfected before use by placing them in a cold sterilization solution for 10 minutes and then rinsing them with sterile water before use. After use, the shank from which the Stabilok pin has sheared off should be disposed of carefully in a sharps container. DRILLS Before first use: Stabilok drills should be sterilized in a standard autoclave cycle. After use: Stabilok drills should have any debris, dentine etc., removed either manually or in an ultrasonic bath, and should then be rinsed and placed in a standard autoclave cycle.

STABILOK DENTINE PINS INSTRUCTION SHEET Overview: Stabilok Dentine Pins are an effective and economical way to provide extra mechanical retention for restorations in both anterior and posterior teeth. Once in place in the tooth, they can be reduced in length and/or bent into the desired position. A major advantage of Stabilok Dentine Pins is that the pin is securely held in a contra-angle shank until it is ready to automatically shear off in the tooth at the correct depth. Preparation of the tooth: The tooth that requires placement of a Stabilok Dentine Pin should be cleared of all caries and dried with an air syringe. In general, a separate Stabilok Pin will be required for each cusp missing. A pre-operative radiograph may be useful in identifying the position and size of the pulp. Procedure for placing the Stabilok Pin: Place a Stabilok Twist Drill in a contra-angle handpiece and latch it in place. With the motor running at a speed of about 2000 rpm drill a hole in the dentine, taking care not to drill accidentally into the enamel or the pulp. The Stabilok Twist Drill has a self-limiting shoulder which prevents drilling too deeply. Once the pinhole has been drilled, remove the twist drill from the handpiece (the twist drill should be sterilized before it is used again). Place a Stabilok Dentine Pin in the handpiece and latch it in place. With the Pin rotating at about 2000 rpm, present the tip of the pin to the opening of the pre-drilled pinhole. The pin will then self-thread to the bottom of the pre-drilled hole and shear-off at the neck formed in the threaded portion. Modifying the Pin: Stabilok Dentine Pins can be modified by either shortening them or by bending them. SHORTENING: To shorten a pin, proceed as follows: Place a high-speed diamond or carbide fissure bur in a turbine handpiece. Position the handpiece such that the bur is perpendicular to the Stabilok Dentine Pin and at a point corresponding to where the pin is to be cut. With the bur running, gently bring the bur into contact with the pin and allow it to cut through the pin from one side to the other. A gentle axial movement of the bur to and fro will facilitate the operation. DO NOT attempt to shorten the pin before it is placed in the tooth because doing so would damage or remove the tapered tip which allows self-threading. BENDING: Stabilok Pins can be bent once after they have been placed in the tooth. An amalgam plugger can be used by applying it to the tip of the pin and gently bending the pin into the position required. The pin should not be bent more than once because repeated bending will weaken the pin and may also weaken its retention in the pre-drilled hole. Disinfection and Sterilization PINS Stabilok pins can be disinfected before use by placing them in a cold sterilization solution for 10 minutes and then rinsing them with sterile water before use. After use, the shank from which the Stabilok pin has sheared off should be disposed of carefully in a sharps container. DRILLS Before first use: Stabilok drills should be sterilized in a standard autoclave cycle. After use: Stabilok drills should have any debris, dentine etc., removed either manually or in an ultrasonic bath, and should then be rinsed and placed in a standard autoclave cycle.

Fully disposable blue polyurethane sponges 811 - For round endo stands, size: 50mm dia. x 8mm 812 - For oval and round endo stands, size: 65mm dia. x 8mm

Fully disposable blue polyurethane sponges 811 - For round endo stands, size: 50mm dia. x 8mm 812 - For oval and round endo stands, size: 65mm dia. x 8mm

For dental needle,endo,drills,block cleaning. Size:6cm Material: Sponge Quantity:50pcs/Box Its soft exterior does not scratch surfaces and the foamy texture allows detergent to spread quickly and easily over the surface for effective clean up. Versatile painter's tool: Ideal for use with oil, watercolor, acrylic and fabric paints. Can also be used for pottery making, face painting and arts & crafts. Keep it in a dry place and avoid sunlight. Remember it is disposable product.

Endodontic Ruler with finger holder -Stainless Steel with calibration upto 35mm